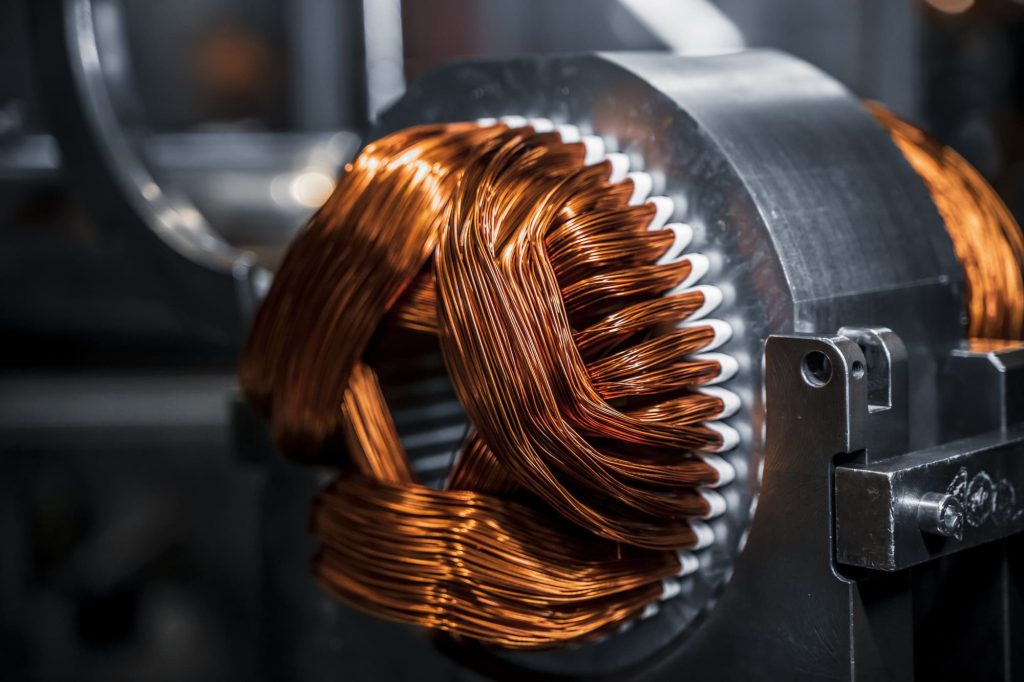

MOTORS

The traction machine motors we manufacture in our Crespellano factory (BO)

- 4/16 Poles 400V – 50 HZ

- AC VF, 4 Poles, 400V – 50Hz

- 6/24 Poles, 400V – 50Hz

- 4/16 Poles, 380V – 60 HZ

- 6/24 Poles, 380V – 60 HZ

Technical specifications of Alberto Sassi S.p.A. motors

General Data

Electrical data

Special Data

A1. General characteristics

Characteristics |

Description |

Reference standard |

|---|---|---|

Other reference standards: NORME IEC/CEI: CEI EN 60034-2-1:2015-09; CEI EN 60034-8:2008-05+A1:2015-01 | ||

Execution |

Sassi Gear flange |

|

Insulation class |

F |

CEI EN 60034-1:2011-03 Sez. 8

|

Service type |

Intermittente S4 |

CEI EN 60034-1:2011-03

|

Intermittence % |

40 % – 60 % |

CEI EN 60034-1:2011-03

|

Mechanical enclosure protection |

IP 21 |

CEI EN 60034-5:2020

|

Vibrations |

Valore efficace della velocità di vibrazione |

CEI EN 60034-14:2018 |

Noise |

CEI EN 60034-9:2005-05 + A1:2008-02 |

|

Environmental conditions |

Altitudine <= 1.000 m Temperatura <= 40° C |

CEI EN 60034-1:2011-03 Sez. 6 |

Electromagnetic compatibility |

CEI EN 61000-6-3:2007 EN 55014-1:2006+A2:2011 EN 55014-2:1997+A2:2008 EN 12015:2020 EN 12016:2013 |

|

A2. Execution: assembly suitable for SASSI gears (MF type)

That is coupling between gear and motor by means of the flange, with overhanging motor.

A3. General characteristics

Motor maximum internal temperature = 155°C

Allowed maximum overtemperature = 100°C

A4. Type of service: intermittent (at 40% and 60%)

The intermittent service occurs when the motor is subject to working cycle after non working cycles.

The allowed intermittent service is:

40% , with 90 or 120 avv/h;

60% , with 180 or 240 avv/h.

The following table shows the theorical division between working time and non-working time according to the scheduled starting hours.

Sts/h |

Total Cycle [sec] |

Working Cycle [sec] |

Non-working Cycle [sec] |

Intermittence [%] |

|---|---|---|---|---|

90 |

40 |

16 |

24 |

40 |

120 |

30 |

12 |

18 |

40 |

180 |

20 |

12 |

8 |

60 |

240 |

15 |

9

|

6

|

60

|

A5. Mechanical enclosure protection: IP21

That is: “Protection against the accidental contact with live parts and against approach to such parts as well as against contact with moving parts inside the casing with one’s fingers or with objects not longer than 80 mm. Protection against the penetration of solid foreign bodies with a diametre more than 12 mm”.

Moreover: “Vertically falling dripping water has no harmful effect.”

A6. Vibrations

According to the standard CEI EN 60034-14:2005-11 + A1:2007-10, the value adopted to measure the vibrations corresponds to the effective value of the vibration speed expressed in mm/sec.

The values normally adopted, concerning the internal standard of acceptability for SASSI machines are lower than the one scheduled by the above mentioned rule.

A7. Noise

The standard adopted to measure noise, complies with what specified by the CEI EN 60034-9:2005-05+A1:2008-02.

As regards two speed motors, give special attention to noise during transients and during working at low speed

B1. Definitions, symbols, unit of measure

The electrical characteristics of motors showed in the following part refer to the symbols and to the definitions reported in the following table.

Definition |

Explanations |

U.M. |

Symb. |

|---|---|---|---|

Synchronous output |

Output calculated from rated torque and synchronous revolutions per minute |

kW |

Ps |

Rated output |

Output calculated from nominal torque and revolutions |

kW |

Pn |

Rated torque |

Torque at nominal revolutions

|

Nm |

Mn |

Starting torque |

Torque at start |

Nm

|

Ma

|

Nominal revolutions |

Revolutions number at rated torque |

RPM

|

Nm

|

Synchronous revolutions |

Synchronous revolutions number, depending on the nominal frequency and on the motor polarity |

RPM |

Ns |

Slip |

Loss of revolutions with reference to the synchronous revolutions |

s% |

|

Rated current |

Current absorbed with load equal to the rated torque |

A |

In |

Starting current |

Current at motor start |

A |

Ia |

No-load current |

Current without load |

A |

Io |

B2. Connection phases: star/delta

All motors are manufactured with the possibility either of a star or a delta connection. Unless different requests, motors are supplied with a star connection.

It is however possible, in case of need, to transform the star connection into a delta one following the instructions reported in the use and maintenance handbook or in the wiring diagram in the motor terminal box.

B3. Thermic protection: thermistors at 145°C

Two rows of thermistors, one in the winding of the low speed and one in the high speed one, are always present in the motor. Their implementation prevents motor burning caused by the overheating of the winding. The implemented thermistors are PTC resistors (with Positive Temperature Coefficient ): the value of their resistance ranges from 300 OHM to about 4000 OHM when the temperature of the winding reaches 145°C.

For a correct use of thermistors it is necessary to have a suitable amplificator able to detect its variations of resistance and to inform the control panel, thus opening a contact which can be used as safety contact of the installation. On request, SASSI can supply this type of amplifier.

B4. Thermocontacts at 70°C (to start the auxiliary fan)

Inside the winding, all motors have two thermocontacts to start possible auxiliary fans. Two thermocontacts are connected in parallel. The electrical characteristics of the thermocontacts are the following:

– maximum tension on the contact: 220 V c.a.

– maximum current on the contact: 1 A c.a.

The thermocontact works as a contact normally open which gets closed as soon as motor temperature reaches 70°C. In this way the fan starts working.

B5. Forced ventilation (when scheduled)

It occurs by means of special fans. Standard fans are fed with a single-phase tension of 220V (50/60Hz). Fan can be assembled on all motors; it is therefore possible, without any difficulty, to mount a fan on a machine which was previously not equipped with it.

Note:

In the following tables the figures relative to the external permissible moment of inertia (Jest) of the motors for the various types of intermitting services (90-120-180-240 sts/h) refer to the implementation of motors without fan for a service of 90 and 120 sts/h (the latter where scheduled) and with fan for 180 and 240 sts/h.

B6. Slip [S%]

The slip of two-speed motors is averagely equal to 8% at high speed and to 25% at low speed.

For VF motors please refer to the specific table.

Example: ( motors 4/16 poles – 50 Hz )

High speed |

synchronous revolutions = 1.500 |

nominal rev. = 1.380 |

|---|---|---|

Low speed |

synchronous revolutions = 375 |

nominal rev. = 280 |

Note:

For each motor the real number of revolutions at full load is printed in the respective plate.

B7. Starting current [Ia]

The starting currents of two-speed motors are averagely equal to:

High speed |

3.8 x In2 |

|

|---|---|---|

Low speed |

1.5 x In1 |

|

Where:

In2 = nominal current at high speed;

In1 = nominal current at low speed.

For VF motors please refer to the specific table.

B8. Tolerances (CEI 2.3 - Sec.9)

The tolerances allowed as regards the values printed in the motor plates refer to CEI rules 2.3 (Section 9). Here follows we sum up the tolerances relative to the most important magnitudes. The values listed in the table represent the increases or decreases ( % ) in comparison to the values printed in the motor plates.

Slip |

+/- 20% compared to the declared slip value

(which can be calculated from nominal rpm) |

|

|---|---|---|

Starting current high speed |

+ 20% |

|

Starting torque high speed |

-15% / +25% |

|

Rated efficiency |

-15% of (1 – efficiency) |

|

Besides the standard characteristics described above, there are some other optional characteristics (delivered on request). Among them we list:

C1. Thermoresistors at 130°C

Provide a double thermal protection of the motor, working as thermal prealarm in those systems which have this possibility. They can be implemented, for example, to enable the cabin to reach the floor when the motor temperature is higher than the one of the thermistors and to prevent its following start as long as the temperature of the windings remains higher than 130°C.

C2. Tropicalization

It occurs by adding another impregnation phase with special fungicide varnishes to the normal motor impregnation cycle (with varnishes suitable to the working class F,155 °C) thus allowing the working of motors even in countries with a hot-humid climate. In case of tropicalization, the allowed motor overtemperature has to be lower than 10°C in comparison to that of F class, thus shifting from 100 to 90°C.