edited by our TECH TEAM.

LORENZO CALVI, Technical manager & FRANCESCO ZENONI, Area Manager

When we talk about installations of very large dimensions, in Alberto Sassi the solution is MB108, the largest geared machine in the catalog range!

In this special case the machine is offered with a new set-up, to meet the needs of impressive systems and at the same time comply with the most advanced regulations.

Let’s see how we designed it:

The PROJECT: a machine for a goods-lift with 15tons duty load, roping 6/, pulley speed 3 m/s with reduction ratio at 4 entrances, that is 4/59

The CHALLENGE: design an isostatic geared machine with a nominal power of 90kW and an emergency brake on slow shaft according to rule EN 81- 20:2020.

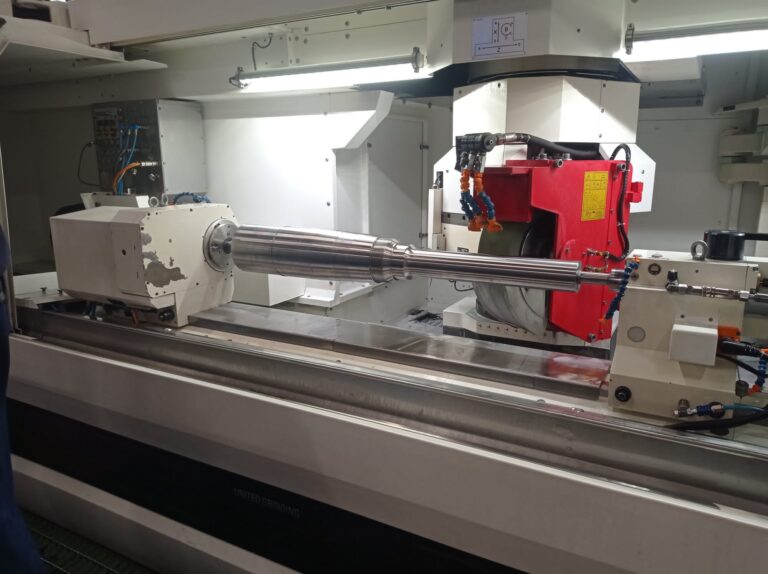

Our SOLUTION: we set up a MB108 with a special integral slow shaft 1/2 meter longer than standard one partiti dal nostro MB108 (1150mm against 650mm).

This special shaft allow the implementation of a double emergency brake (4 discs in total) with a supporting structure integrated to machine’s frame. This special execution with MAYR brakes was developed by the German company FUKA and allows a total braking torque of 6240Nm to be reached.

The ADDED VALUE OF THIS SOLUTION: we managed to mount the brake against uncontrolled movements on a machine for capacities of up to 200 people with a traction shaft on only two support points (external support and outstanding wormwheel).

This execution is from now available for any usage as standard application on request.

Form left: Alessandro Albertazzi, R&D Sassi – Lorenzo Calvi, Technical Director Sassi. –

Manuel Noe Technical manager Fuka- Torsten Fuka, Managing Director Fuka